|

COMPUPLAST® Seminar and WorkshopExtrusion Process Engineering and TroubleshootingSept 23 – 25, 2025, Buffalo NY |

|

Dates:

September 23 – 25, 2025

9:00am-5:00pm (Each Day)

REGISTRATION FEE: 3-Day Workshop US$1,950

**$300 Discount for Registering before August 29nd, 2025 with Promo Code “SAVE300” **

REGISTRATION LINK

*We will reply within 24 hrs to confirm your registration request. Note that your registration is not guaranteed until payment has been received and we have sent you a confirmation of your registration. Space is limited so book early.

LOCATION:

The Delavan, Hotel and Spa

6461 Transit Road

Buffalo, NY 14043

DISCOUNTED HOTEL RATE:

Call the Delavan Hotel and Spa at

(716) 635-9000 or (877) 456-4097

and request the COMPUPLAST rate.

OVERVIEW OF SEMINAR

This seminar has been developed to help participants better understand what happens inside their extrusion equipment. They are introduced to a more scientific approach to extrusion, which helps them learn the root cause of many extrusion problems and then learn how to solve, or avoid them all together. The extrusion engineering concepts are presented in a very practical manner and re-enforced through many “case study” style examples. Upon completing this seminar, the attendees will have a good understanding of how polymers behave inside extrusion equipment and how to apply engineering methods towards the analysis, design or troubleshooting of any extrusion process.

WHO SHOULD ATTEND

This course is intended for anyone who is currently (or training to become) responsible for the design or performance of an extrusion process. Extrusion process engineers, technical service personnel, screw and die designers, research and development personnel and particularly, those responsible for troubleshooting extrusion processes will obtain the most benefit from the information presented.

WHAT WILL YOU LEARN

This seminar will show attendees how to properly evaluate and analyze extrusion equipment using sound engineering principles. Process Engineers will learn how to properly analyze and troubleshoot their equipment in order to optimize performance. Designers will learn about the most important design criteria that should be used for extrusion equipment. Attendees will also get a good appreciation about the types of CAE tools available for extrusion and how to interpret them properly.

The seminar will introduce practical rheology (polymer flow behavior) in a clear and straightforward manner as it applies to the process operations that will be presented. The focus is on the rheological characteristics of the polymers that are most important to the understanding of the extrusion process and to the design of the equipment. After this seminar, the attendees will be better qualified to select materials and to differentiate between equipment design, which can be a big benefit during future product development or equipment specification and selection.

|

|

|

IMMEDIATE BENEFITS

- Gain a better understanding of the extrusion process.

- Learn how to avoid and solve many extrusion problems.

- Learn how to distinguish between a “good” and “poor” screw or die design.

- Learn the material properties that are the most critical to your process.

- Learn how to determine and monitor extruder performance efficiency.

- Learn how to improve product quality, and reduce/eliminate degradation.

- Learn how to maintain screws and increase their longevity.

- Receive a 3-month trial license of extrusion simulation software.

- Receive a 1-year membership to the Society of Plastics Engineers

TESTIMONIALS

- “This course was so useful for my job. These are the types of courses we need more of. This was money well spent.”

- “I believe this was the most interesting, well organized, and valuable internal course I’ve had the pleasure of attending. Thanks”

- “Excellent instructor. Well-organized course.”

- “Very well organized, very practical. Better than the previous Rheology course I took!”

- “This was a great course. I learned a lot that I can directly use for my job.”

- “Course material was excllent! It was great to get to know the instructors during lunch and other informal times. You were very approachable.”

- “I was very pleased with the hospitality given by the Hotel and Compuplast. I felt they went above and beyond on what they had to do, but very much appreciated. Thank you.”

3-Day Extrusion Process Engineering and Troubleshooting

OUTLINE:

Day 1 – Tuesday September 23rd, 2025

Morning Session: Polymer Rheology

The attendees will learn about the most important rheological measurements (such as shear viscosity), what they mean, how they are obtained and, most importantly, how they affect the extrusion process.

Attendees will be shown how to use the Compuplast® Virtual Extrusion Laboratory™ (VEL™) Material Properties module to fit viscosity data to models and then use the data for calculations.

Main takeaways:

- Learn which material properties are most important for extrusion.

- Learn which material properties must be measured and how they must be measured.

- Learn how to use VEL™ Material Properties module to fit viscosity data

- Learn how to compare different materials.

- Learn how to size an adaptor or any flow channel.

Afternoon Session: Extruder Performance (single-screw only)

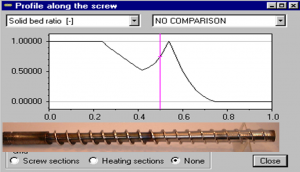

This part of the seminar will describe the functions and the requirements of a single screw extruder using both, a combination of theory and videos of experiments performed on glass window extruders. The main principles of operation are reviewed and design parameters and variations are explained, from a CAE point of view. The Compuplast® Virtual Extrusion Laboratory™ (VEL™) Extruder module will be used to re-enforce the theory presented and to demonstrate the effect of screw design, operating conditions and material changes on melt quality.

Main takeaways:

- Learn how to distinguish between a poor and a good screw design.

- Learn how polymers behave inside conventional and barrier screws.

- Learn the important design criteria for the flow channels of a single and barrier screws.

- Learn about different mixing elements and how to design their flow channels.

- Learn how to analyze and troubleshoot conventional, barrier, and vented screws.

- Learn how to simulate an extruder using the Compuplast® VEL™ Extruder module

- Learn how to engineer the screw to deliver the required output and produce the optimal melt quality.

- Learn how to improve process stability and reduce scrap rates.

- Learn how to monitor and compare extruder performance.

TESTIMONIALS

- “One of the best courses I have attended in years. Application of Rheology was very practical in this course.”

- “I really enjoyed this course. It was very relevant and provided a lot of useful information and insight. The speakers were excellent!”

- “Very good! I learned a lot about “real world” applications of rheology for PE.”

- “Found course very useful, liked that it was very application related (I.e. extruder, dies, screw) and that there were many real world (practical) examples given. Presentation slides were excellent. Windowed extruder slides very useful.”

- “Very informative course, probably the most in depth course directly related to the extrusion process and the tooling related to that process. I would highly recommend this course to any technical staff working in the extrusion field, and am recommending this to our colleagues from other facilities.”

Day 2 – Wednesday, September 24th, 2025

Flat Dies, Annular Dies and Profile DIes

|

|

|

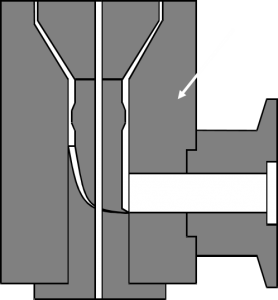

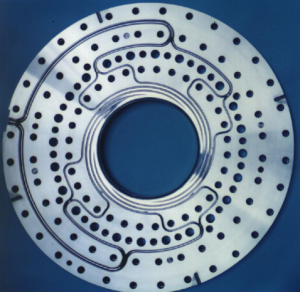

This part of the seminar will describe the functions and the requirements of various types of annular and flat type of extrusion dies. “Annular” dies are used to produce tubular products such as film, pipe, and tubing while “Flat” type dies are used for the production of flat/cast film and extrusion coating. The main principles of operation are reviewed and design parameters and variations are explained, from a CAE point of view. The VEL™ Flat Die and Spiral Die modules will be sued to re-enforce the theory presented and to demonstrate the effect of channel designs, operating conditions and material changes on die performance. This session will also introduce the Compuplast® Cross Flow Minimization™ method for Profile Die engineering. The details and benefits of this method will be explained using real world examples.

Main takeaways:

- Learn the important design criteria for the flow channels of a flat die, spider die, side-fed/cross-head die, spiral die, and flat spiral die.

- Learn how to troubleshoot flat and annular dies.

- Learn how to analyze, optimize and troubleshoot flat dies that are used in mono and multi-layer extrusion of sheets and flat films.

- Learn how to analyze, optimize and troubleshoot annular dies used in the production of blown-film, pipes, tubes, blow molded parts and other annular products.

- Learn how to improve distribution and reduce/eliminate degradation.

- Learn how to maximize production rates.

- Learn how to increase process consistency and broaden the processing window of the die.

- Learn the important design criteria for the flow channels of a profile die whether it is for construction, automotive or medical applications.

- Learn how to reduce die development time and broaden the processing window of a profile die.

- Learn how to increase productions rates in profile extrusion.

TESTIMONIALS

- “Outstanding presentation gentlemen. I am completely satisfied.”

- “I was truly amazed with the way the instructors led the course from the start of the process through to the material coming out of the die and how well they tied all of the elements together to allow the students to fully grasp all of the conditions that affect the outcome of a process. This approach removed a lot of the mystery surrounding the extrusion process and allowed me to focus more on the contributing factors at play. The element of die design was very thorough, and I will now use the term “Die Design” with the respect it deserves. Excellent course.”

Day 3 – Thursday, September 25th, 2025

Coextrusion, Cooling and Polymer Degradation

|

|

|

On the 3rd day, the topic of Coextrusion will also be discussed along with some design strategies for avoiding problems such as interfacial instabilities. Some of the Compuplast® VEL™ modules will be used to demonstrate and re-enforce the concepts presented. Finally, we will finish off with a session on general extrusion troubleshooting and polymer degradation, some of the major causes and how to avoid problems.

Main takeaways:

- Learn the important design criteria for the flow channels for coextrusion.

- Learn how to identify interfacial instabilities during coextrusion and how to correct them.

- Learn about cooling analysis and the bestway to increase output.

- Learn how to troubleshoot extrusion problems.

- Learn how to reduce/eliminate polymer degradation.

TESTIMONIALS

- “Fantastic presentation gentlemen, I’ve been in the industry (in Research & Development) for 25 years, and I took your course 20 years ago. The material is up to date, practical, and in many instances immediately useful to addressing production issues; whether material or equipment based.”

- “I thought the theoretical introduction was very good at setting everything up to understand the simulations.”

- “After this seminar, this was the first time I really ever understood what we do all day!”

- “Great course. Wish I had attended course 10-15 years ago!”

REGISTRATION:

**$300 Discount for Registering before August 22nd, 2025**

To register and pay via credit card/check, please click on the link below:

REGISTRATION LINK