Eliminate “Unmelts” in Product

What was the problem?

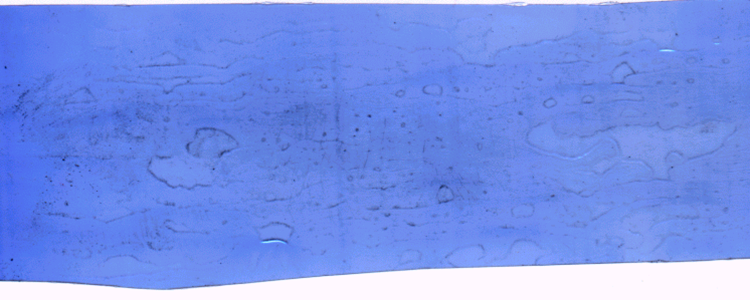

Unmelts in Product!

The customer was seeing periodic showers of unmelted particles in their film. The line would have been running normally, and then suddenly, unmelted particle would appear in the film, and then the line would run normally again.

What was the root cause?

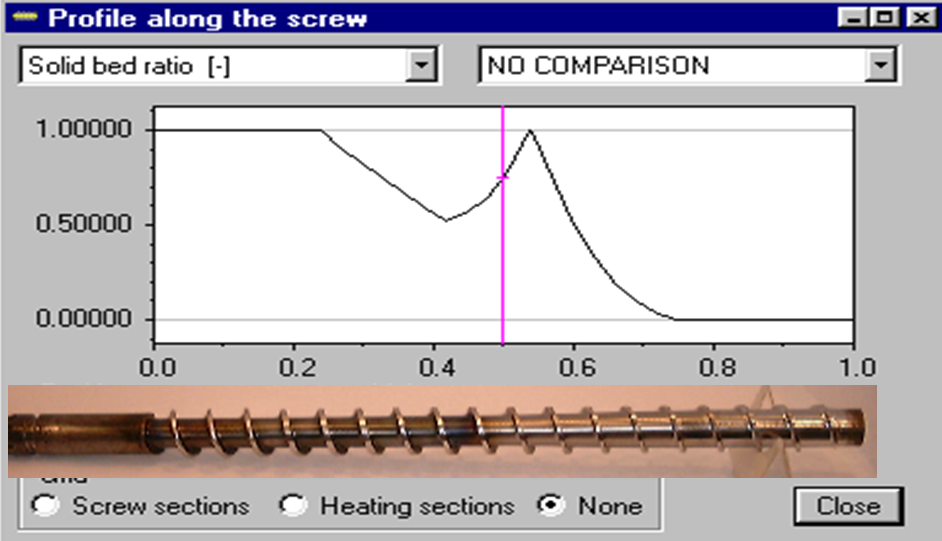

Solid-bed break up in screw!

After analysing the scew, we found that the compression section was too short. The rate of compression was faster than the rate of melting, which resulted in impregnation of the solid bed by them melt pool, which resulted in solid-bed breakup. When the solid bed broke up, it disrupted the melting process and the solid particles were insulated from the barrel wall by the melt pool. These solid particles would spin in the channel and would slowly melt by conduction. When they became small enough, they were released and appeared in the product.

How it was solved?

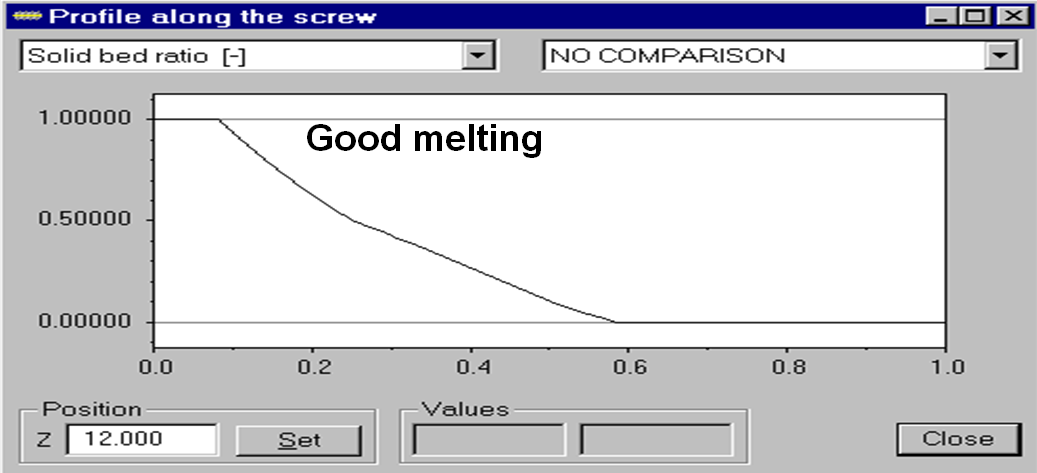

Redesign the screw to ensure solid-bed break up does not take place!

We analysed the die using the VEL Extruder Module. We optimized the screw so that the solid-bed ratio gradually decrease from 1 to 0, which indicates that solid-bed break up will not take place.

After the optimized screw was bulit, the customer did not get periodic shower of unmelts in their product.

Bottom Line

Normally, it would have taken a long time to simply figure out where the problem was coming from. Using simulation, we were quickly able to find the root casue of the the problem and hence find a solution much faster. The customer saved thousands of dollars and their scrap rate was significantly reduced.