Increase Profile Production Rate

What was the problem?

Low Production Rate!

To meet their deadline, the customer had to produce this profile at >10 ft/min. Unfortunaltely, the die was balanced at 1 ft/min, and he could not increase the production rate without modifying the die. They did not have enough time to go through his normal trial-and-error process.

What was the root cause?

Cross-flows!

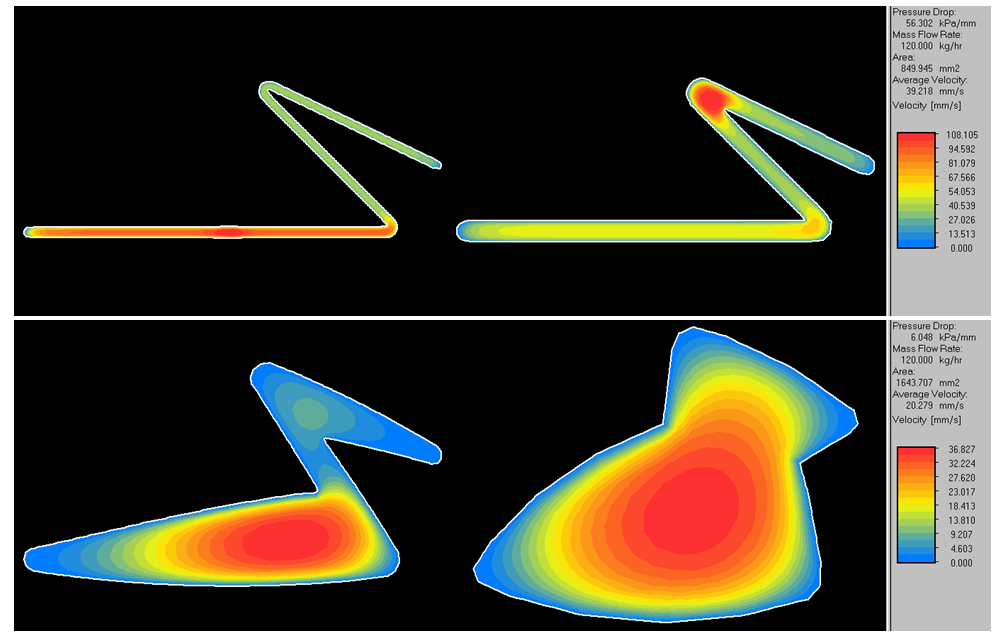

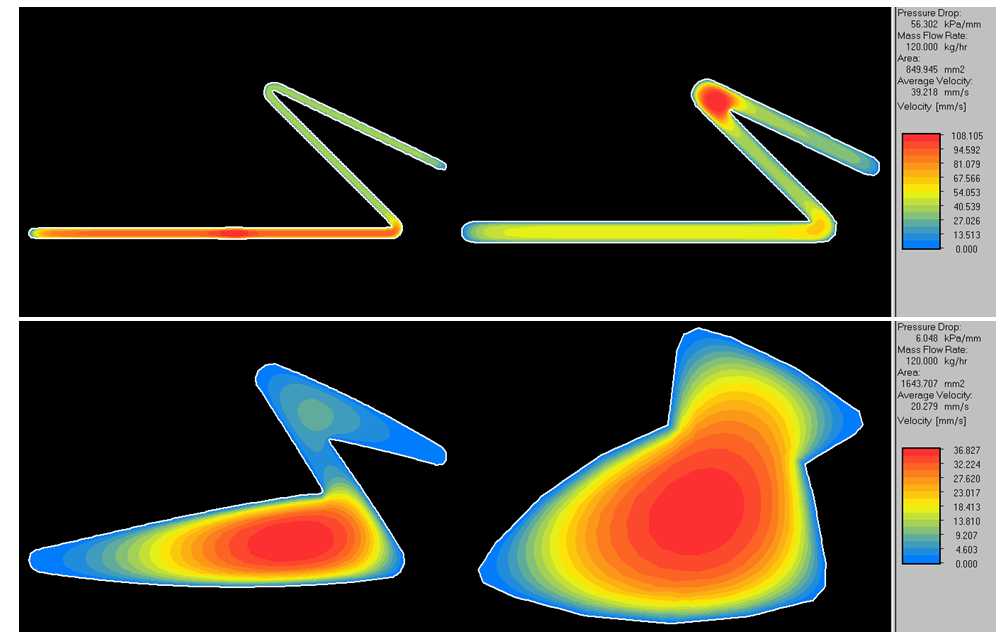

After analysing the die, we found that the die had been balanced by land, which created cross-flows in the die. When this occurs, the die is balanced only at the production rate and conditions that were used during the balacning iterations. If the production rate is increased (or decreased), the die can become unstable.

How it was solved?

Balance the melt flow and minimze cross-flows!

We analysed and balanced the die using the VEL Profile Die Module and Compuplast’s Cross Flow Minimization Method. The die cross-sections were modified so that the flow in each cross section of the die was balanced and cross-flow were minimzed.

The dies was built using the optimized cross-sections. The customer was able to develop the die much faster than before, as most of the trial-and-error was conducted on the computer. More importantly the customer was able to acheive a production rate of 18ft/min. The die was also more robust – less sensitive to changes in process conditions.

Bottom Line

Thanks to our VEL Profile Die Module and Compuplast’s Cross Flow Minimization Method, the customer was able to their production rate by 600% and meet their deadlines.