Eliminate degradation in adaptor

What was the problem?

Material degradation in a PVC Flat die!

The customer observed degradation in the transition region between the region after the breaker plate and die. Material would stagnate in that region and degrade over time. This problem was so severe that the customer had to stop the line, remove the degraded material and start the line – every shift!

What was the root cause?

Low Shear Stress at the wall!

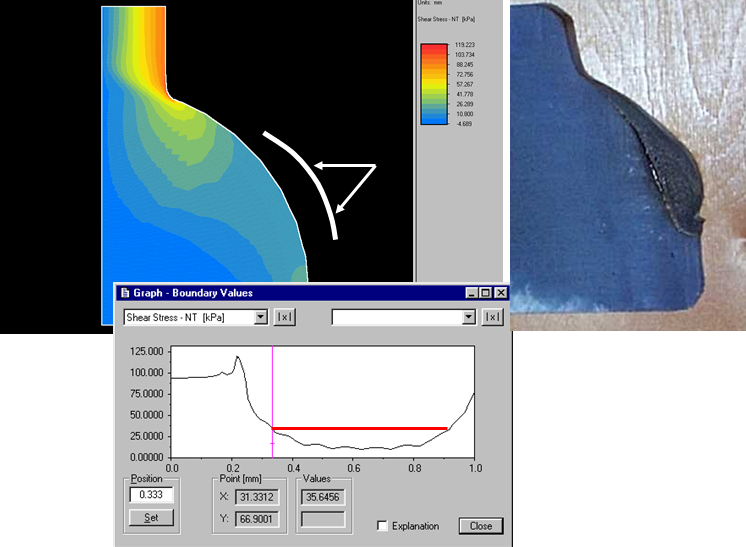

Adequate shear stress at the walls is required to keep the system “self-cleaning”. After analysing the geometry, we found that shear stress near the walls of the transition region was too low, which led to build up of material, which eventually degraded.

Adequate shear stress at the walls is required to keep the system “self-cleaning”. After analysing the geometry, we found that shear stress near the walls of the transition region was too low, which led to build up of material, which eventually degraded.

How it was solved?

Increase the shear stress near the walls!

We analysed the die using the VEL 2DFEM module and calculated the shear stress. We then modified the geometry until the shear stress at the walls went above the minimum required value.

After the new transition was built, the customer could run the line for weeks. There was no longer any degradation in this manifold section region.

Bottom Line

Stopping and starting the line to remove degraded material is prohibitively expensive. Furthermore, degradation of PVC releases harmful and poisonous gases which can be hazardous to the health of the employees in the plant.

By using simulation, we were able to find the root cause of the problem and find the optimized geometry in less than 2 hours. The solution saved the customer thousands of dollars every year.