|

|

|

|

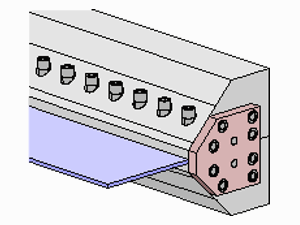

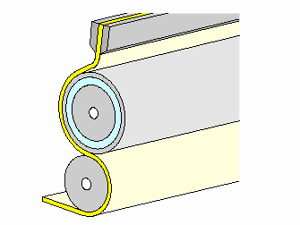

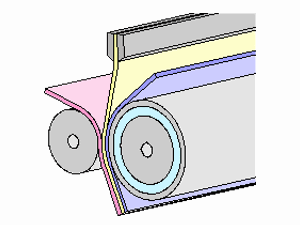

| Sheet Extrusion | Cast Film Extrusion | Extrusion Coating | Blown Film Extrusion |

|

|

|

|

| Profile Extrusion | Pipe Extrusion | Cable Coating | Extr. Blow Molding |

|

|

|

|

| Medical Applications | Extruder | 2DFEM | 3DFEM |

Compuplast’s Virtual Extrusion Laboratory (VEL) is a state-of-art simulation software developed specifically for the polymer extrusion industry. This software has helped hundreds of companies save a tremendous amount time, material, and money, by:

- reducing development times,

- increasing production rates,

- increasing process consistency, and

- predicting extrusion problems.

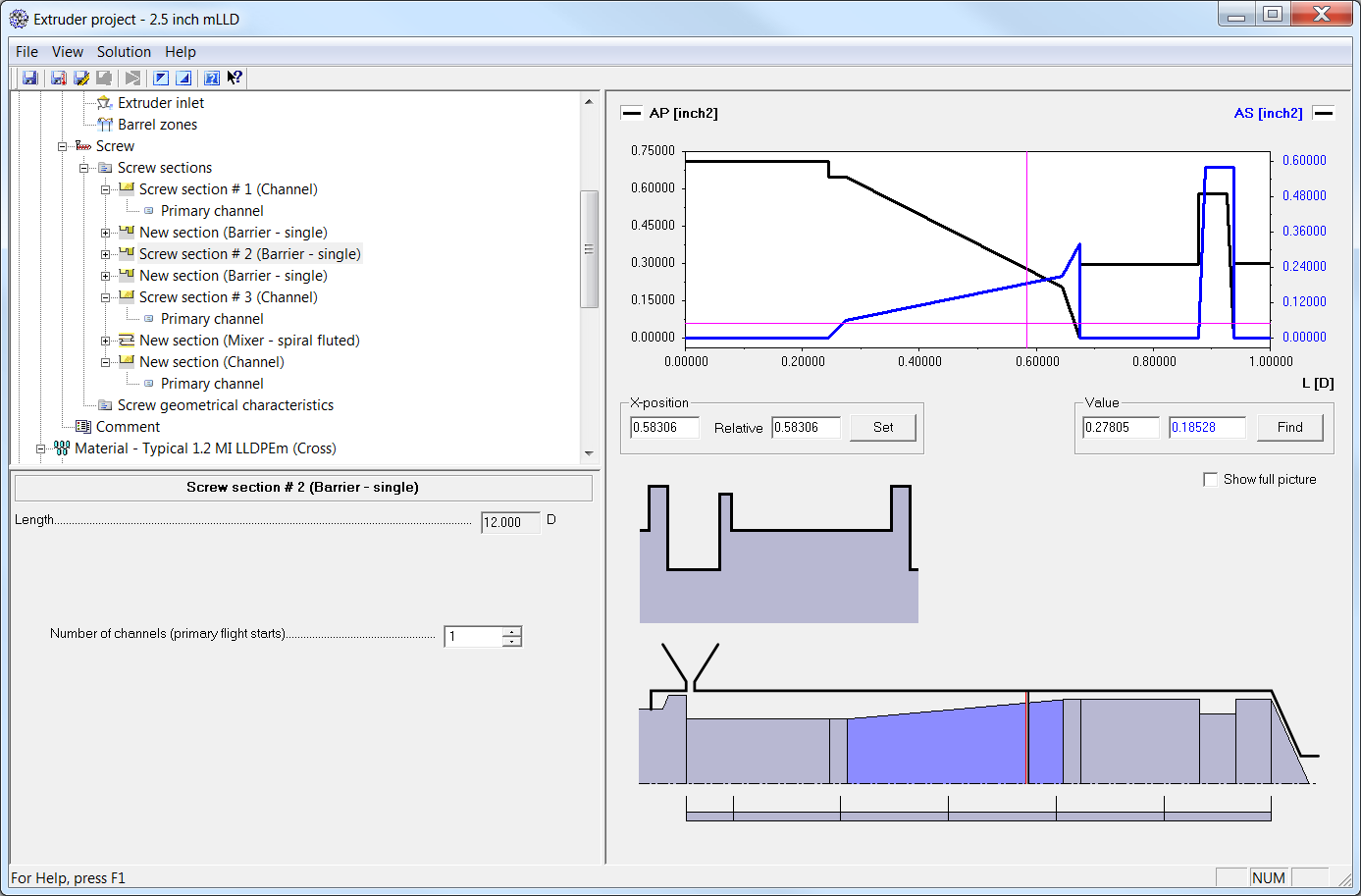

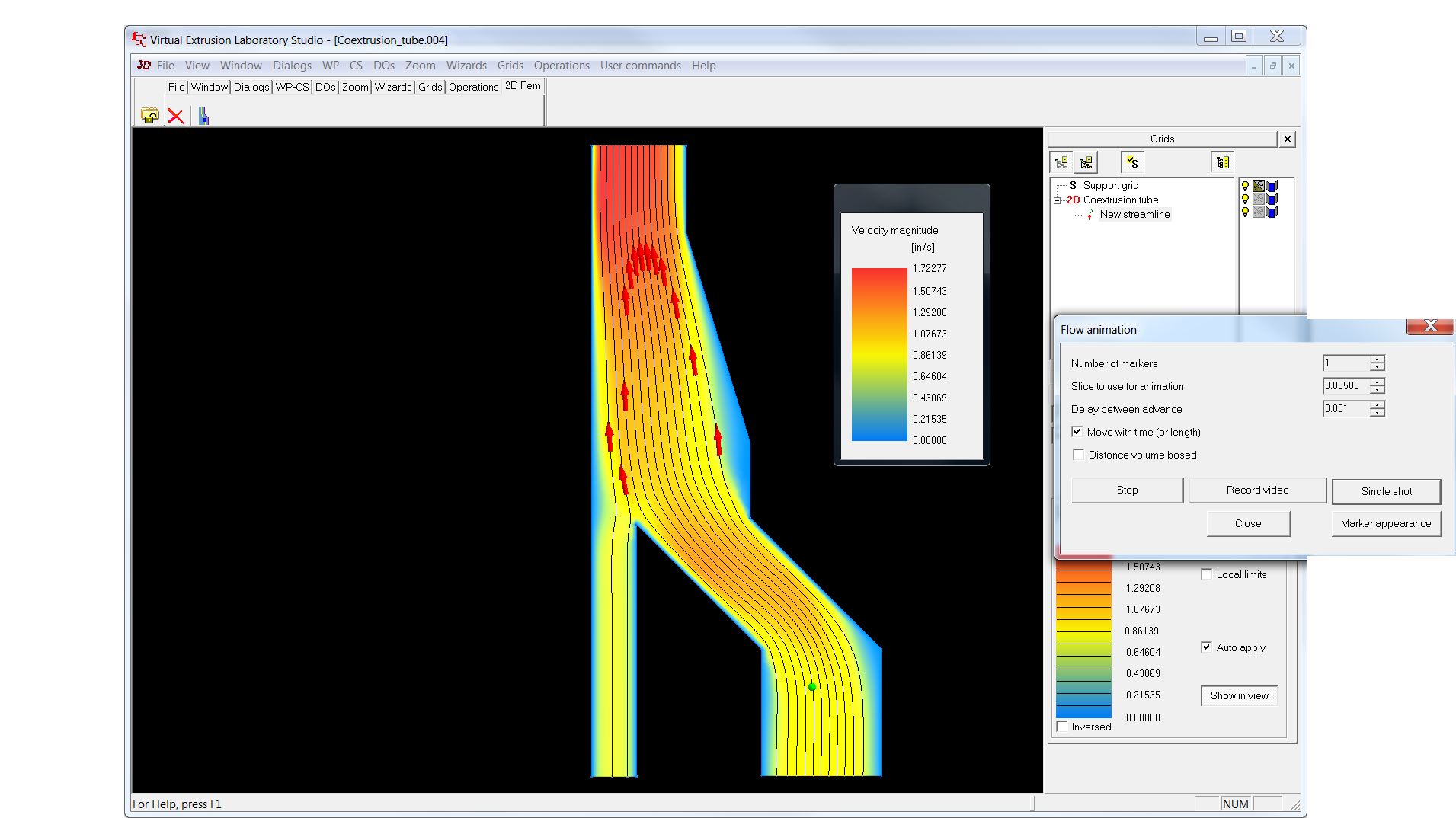

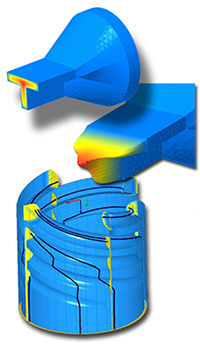

VEL allows companies to “experiment” in a virtual environment. Using VEL, single-screw extruder’s and dies can be designed and optimized for high process consistency and required production rates. These designs can then be tested without cutting any steel or wasting any resin. Numerous extrusion problems can be detected and “nipped in the bud” in the design phase.

VEL is also a powerful tool for analyzing and solving existing extrusion problems. When an extrusion problem appears, it has hard to determine whether it is caused by the material, extruder, and/or die. VEL helps the engineer identify the root cause of the problems and then helps the engineer find a solution much faster. Below is a partial list of extrusion problems that have been analyzed and solved using VEL:

- Degradation

- Unmelts/Gels

- Catastrophic screw failure

- Poor die distribution

- Die drool

- Interfacial instabilities

- Distorted profiles

- Low production rate

- Low process consistency

- High scrap rates

- Out of control melt temperatures

- etc.

VEL can also be used to help speed-up the learning curve for new employees. By using VEL and working with Compuplast’s Extrusion Experts, employees can gain the experience of an industry veteran in 1-2 years.